Purification

A partner for every aspect of the solvent lifecycle

We are an integrated industrial company specializing in the production of high-purity solvents, recovery and purification, packaging, marketing, and distribution of a wide range of solvents and formulations. We also offer contract manufacturing services through dedicated and flexible production, distillation, and chemical synthesis lines, tailored to the needs and quality specifications of various industries and applications.

What We Offer

The Technological Process

Located on an area of over 75,000 m² southeast of Milan, our Landriano production plant is a modern, complex distillery developed over time with the goal of offering maximum flexibility through high-efficiency multipurpose systems.

Read more

Alongside dozens of columns and equipment designed for various distillation processes, the facility includes a dedicated synthesis department that has become highly specialized in custom manufacturing over the years. The production plant and its storage tanks have a total capacity of approximately 200,000 tons per year, of which around 100,000 tons per year are authorized for the recovery and regeneration of organic solvents.

The facility also includes two modern laboratories.

An advanced in-house engineering department, supported by state-of-the-art simulation software, continuous investments in improvement and innovation, and over thirty years of experience, have enabled the ongoing enhancement of our systems, which currently include:

- Continuous and batch fractionating columns

- Maximum system assembly flexibility to adapt equipment trains even for series processes

- Multiple types of hot/cold fluids and vacuum systems, allowing for unique operating conditions compared to competitors

- Extensive authorization for the storage of flammable and toxic products

The plant and its technologies are supported by ISCC PLUS and ISCC EU certification systems.

Certifications

Itelyum Purification adopted the Quality Management System in compliance with ISO 9001 in 2010, the year in which the company obtained its first certification. In 2021, the company achieved its goal of establishing an Integrated Management System that includes, in addition to Quality Management (ISO 9001), Occupational Health and Safety Management (ISO 45001), and Environmental Management (ISO 14001). The integrated certification covers both Itelyum Purification sites, located in Landriano (PV) and Rho (MI).

Read more

The Integrated Management System plays a key role for Itelyum Purification in pursuing its mission to create value by providing customers with products and services that meet the highest quality standards, while also ensuring the well-being of its employees, protecting the communities living near its facilities, and safeguarding the surrounding environment.

Product quality is guaranteed through structured business processes and reproducible production procedures. This applies both to the production of virgin products and to those derived from the revalorization of chemical process residues (Diluents).

Product quality is further ensured by the Quality Control Laboratory, which underwent a major upgrade in 2023 with the near-complete renewal of its analytical instrumentation. A next-generation chromatographic data management system was also introduced, reducing paper use and contributing to the company’s sustainability goals in line with the continuous improvement principles of ISO 9001.

In 2024, Itelyum Purification obtained ISCC EU (International Sustainability and Carbon Certification), which applies to biocomponents and bio-liquids used in the production of biofuels.

In 2025, Itelyum Purification achieved ISCC PLUS certification (International Sustainability and Carbon Certification), which applies to substances (solvents) obtained through the revalorization of chemical process waste. These SFW (Solvents From Waste) represent a valid alternative to virgin solvents, contributing to the reduction of greenhouse gas emissions.

Locations and Commercial Presence

The industrial excellence of Itelyum Purification is built upon two strategic assets: the production plant in Landriano (PV) and the packaging and distribution site in Rho (MI). These state-of-the-art facilities, constantly upgraded and compliant with the most stringent international standards, are not only specialized in complex chemical processes but are also authorized and equipped for the safe storage of flammable and toxic products.

Read more

Their core business spans from the production, marketing, and distribution of solvents—including high-purity grades essential for the most demanding industries—to the critical processes of organic solvent recovery and purification, as well as chemical and pharmaceutical synthesis activities.

This vertical integration of processes ensures total control over the supply chain and guarantees the highest quality at every stage—from recovery to the delivery of the final product.

Thanks to its strong production, logistics, and safe material-handling capabilities, combined with continuous investment in Research & Development, the company has established itself as a strategic partner for the industrial and pharmaceutical sectors.

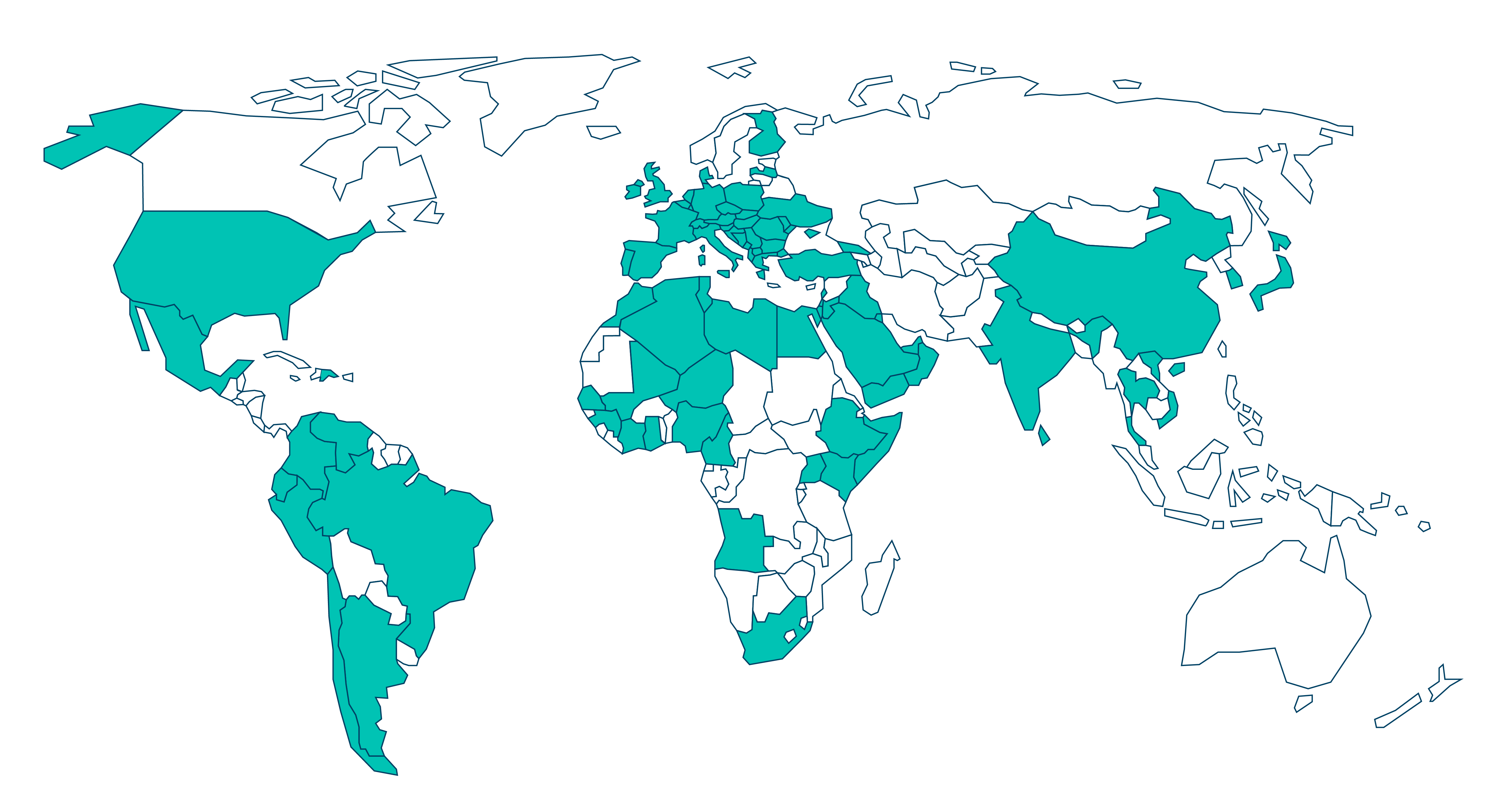

On this solid foundation, Itelyum Purification has built its global presence, exporting its products to over 55 countries worldwide. Its market strategy is based on a comprehensive commercial network—both direct and indirect—meticulously designed to ensure not only efficient distribution but also expert consulting and support, providing customers with the best and fastest commercial service on an international scale.

At the Landriano plant

we regenerate at least 81%

of the raw materials and processed waste streams.

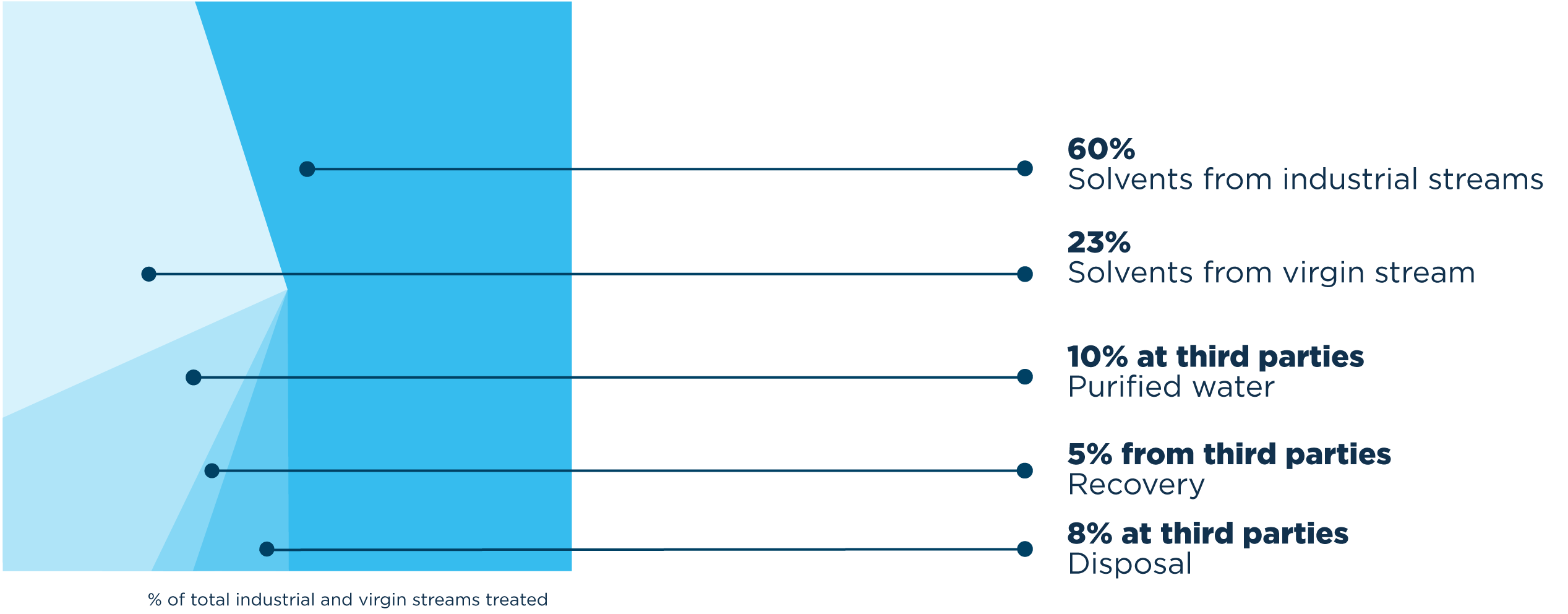

The solvent supply chain

Each year, approximately 90,000 tons of used solvents, primarily from the chemical and pharmaceutical industries, are regenerated or recovered with high industrial yields and quality standards.

This activity, in particular, establishes a strategic partnership with the chemical sector of API (Active Pharmaceutical Ingredient) manufacturers. The products can either return to their original sector (toll manufacturing) or be revalorized through new formulations capable of meeting the needs of other markets, both industrial and geographical.

- Thanks to the technologies adopted by Itelyum, compared with primary production, purified solvents generate:

- Up to 10 times less CO₂ emissions

- 4 times less fine particulate emissions

- 5 times less acidifying emissions (NOx, SO₂, and NH₃)

- Half the water resource consumption

- 8 times less land use

Sustainability in Numbers

Itelyum Purification is committed to improving its ESG performance and transparency through reporting.

This is achieved through a combination of data collection and verification, internal audits, facility self-assessments, and reviews of management systems at site, functional, and corporate levels. Key Performance Indicators (KPIs) are used to measure and communicate overall performance externally.

Find out more

Download Area

Certifications, Authorizations

and Other Useful Resources

Download the documents to learn more about our activities.

Find out more

News and Press Releases

Find out more

Our History